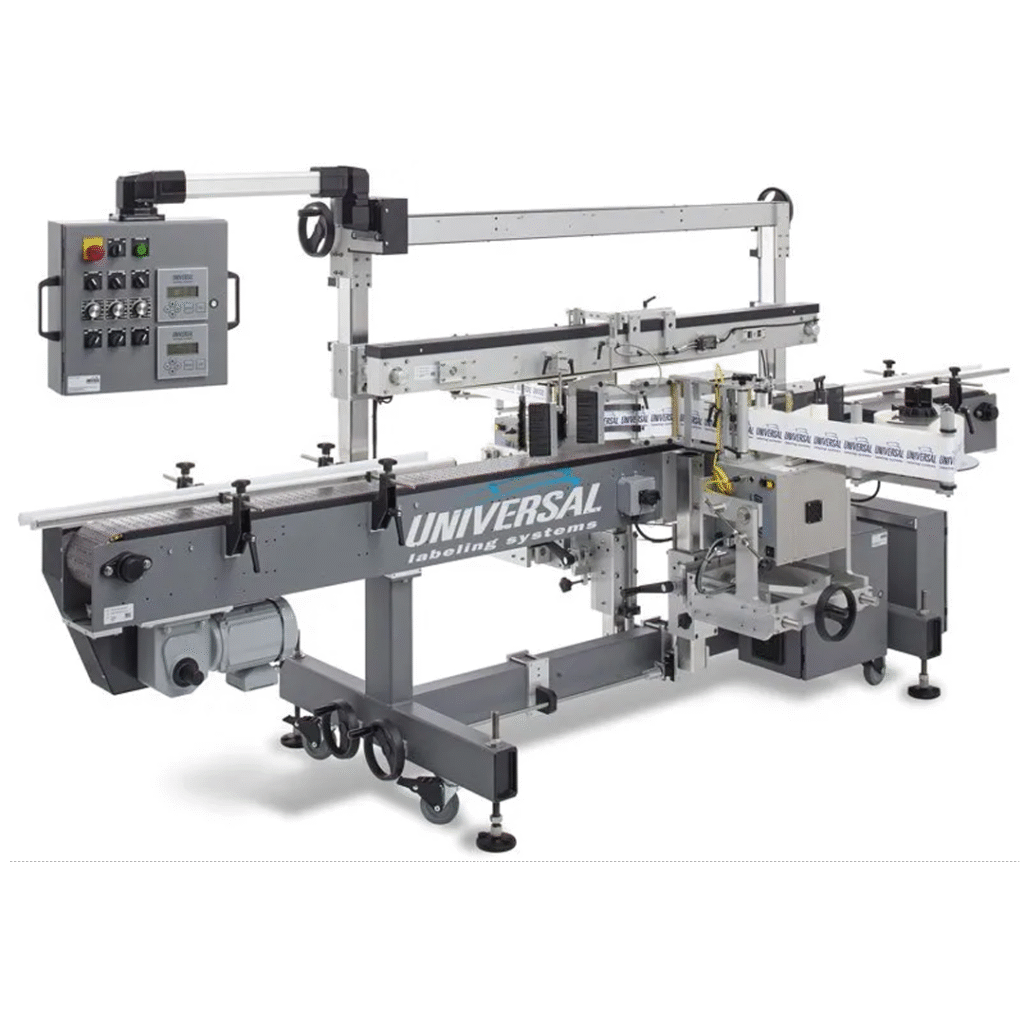

The Universal CP1000 Packager Labeling System is engineered to outperform standard front & back labeling machines by delivering industrial-grade automation, unmatched accuracy, and flexible product handling. Built for demanding production lines, the CP1000 is ideal for food & beverage containers, pharmaceutical bottles, chemical jugs, and cosmetic packaging—making it one of the most versatile automated labeling systems in the industry.

Key Features of the CP1000 Labeling System

- Heavy-Duty Framework – Industrial-strength construction ensures long-term durability.

- 6” Wide x 12’ Long Delrin Chain Conveyor – Smooth, stable transport for products of all shapes.

- Dual SL1500 Stepper-Driven Label Applicators – High-speed label application with precision control.

- Front & Back Labeling Capability – Apply labels to F-style containers, oval bottles, square bottles, and one-gallon jugs.

- Multi-Side Labeling & Orientation – Efficient changeovers allow orientation and labeling of multiple surfaces.

- Photoelectric Product Sensor – Accurate product detection for consistent application.

- Synchronous Product Positioning & Overhead Hold-Down – Ensures label placement accuracy at high speeds.

- Encoder with Speed Following Control – Maintains synchronization across production speeds.

- Secondary Wipe-Down Devices – Guarantees firm adhesion on all products.

- Label Roll & Web Capacity – 12” OD roll with 3” core, 6.25” wide web, up to 1500 ipm dispense speed.

- UL Certified NEMA 12 Control Enclosure – Safety and compliance built into the system.

- Job Save Option – Store and recall labeling setups to reduce downtime.

Technical Specifications

- Dimensions: 83.7″ W x 144″ L x 67.3″ H

- Label Dispense Speed: Up to 1500 ipm

- Label Roll Capacity: 12″ OD, 3″ core

- Web Width: Up to 6.375″

- Electric: 120 VAC

- Shipping Weight: Approx. 1500 lbs

Applications of the CP1000 System

The CP1000 is a multi-purpose packaging automation solution designed for:

- Food & Beverage Labeling – Bottles, jars, and jugs.

- Pharmaceutical Labeling – High-accuracy compliance packaging.

- Cosmetic Packaging – Oval and square bottles with decorative labels.

- Chemical Containers – Durable labeling for industrial products.

Available CP1000 Parts & Accessories

Elmark offers a complete range of replacement parts and accessories to keep your CP1000 labeling system running at peak efficiency:

- Relays: 24 VDC, 30A DPDT; 24 VDC, 6A SPDT

- Power Supply: 24VDC, 1.0 AMP

- Inverters: 1/2HP, 1/8HP, 1/4HP AC Frenic-Mini

- Disconnect Switch: 2-Pole, 440V, 20A

- Fiber Optic Cables: Bifurcated, Barrel Tip

- Sensors: SmartEye EZ Pro (EZPRC), Photoelectric

- Motors: 1HP, 1/4HP, 1/10HP Brother motors (3-Phase)

- Control Boards: SL Series control & display interface assemblies

- Belts: Multiple timing belts (urethane, seamless, padded, clear, and super-grip)

This ensures your packager system stays reliable, efficient, and fully supported.

Why Choose the Universal CP1000 Labeling Machine?

- Higher speed, accuracy, and efficiency than standard contract packager systems.

- Versatile applications across industries and container types.

- Durable design with heavy-duty construction for continuous operation.

- Cost-effective automation that reduces downtime and improves ROI.

The Universal CP1000 Packager Labeling System is engineered for manufacturers who demand speed, precision, and versatility in their labeling operations. With dual SL1500 stepper-driven applicators, a heavy-duty framework, and a 12’ Delrin chain conveyor, the CP1000 delivers accurate front, back, and multi-side labeling on bottles, jugs, and other containers at speeds up to 1,500 ipm. Advanced sensors, encoder synchronization, and secondary wipe-down devices ensure labels are applied consistently and securely, even at high speeds. Built for durability, seamless integration, and flexible product handling, the CP1000 provides industrial-grade automation for food & beverage, pharmaceutical, cosmetic, and chemical applications—offering a cost-effective solution that maximizes efficiency, reduces downtime, and enhances overall production ROI.

Contact Us Today for Pricing