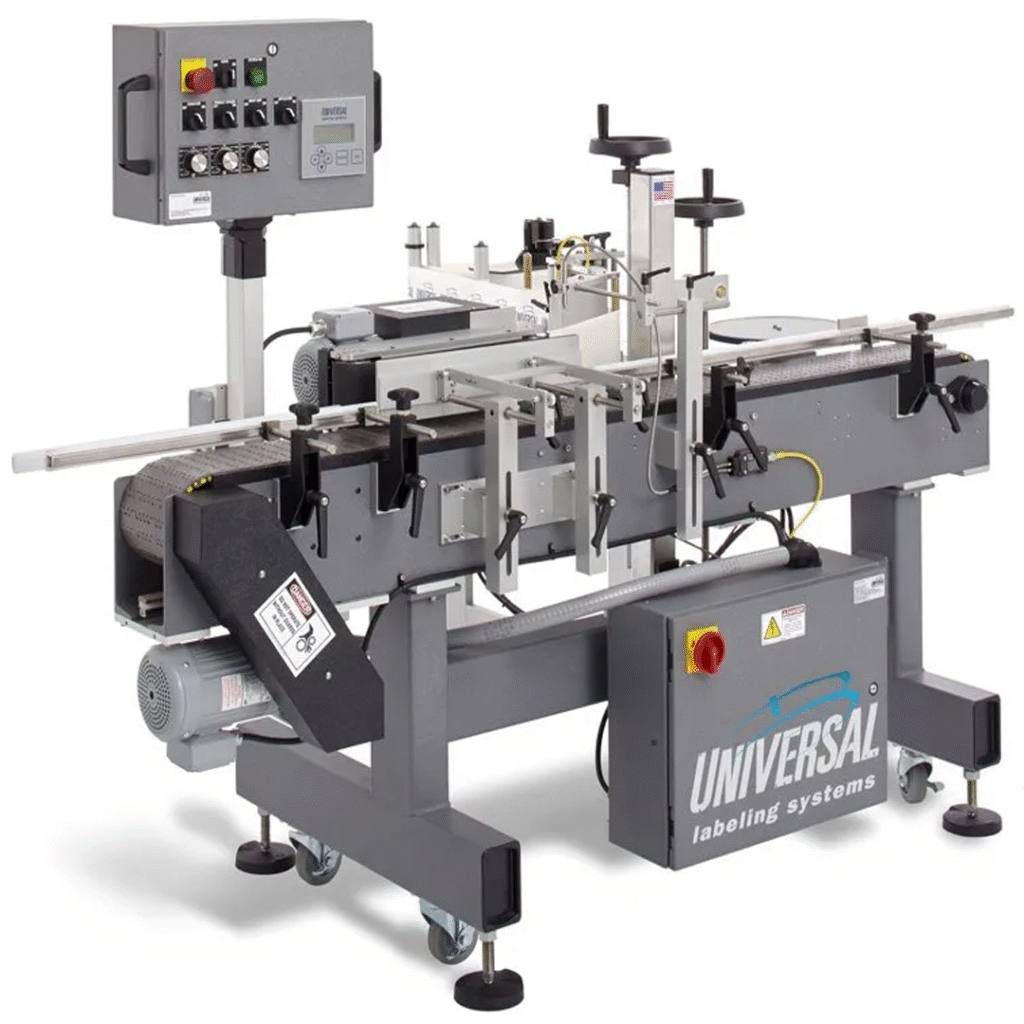

The Universal R322 High Speed Round Product Labeling System delivers unmatched accuracy and productivity for automatic round product labeling. Designed with a heavy-duty system framework and premium industrial components, the R322 is built to handle demanding applications in food and beverage, pharmaceuticals, cosmetics, and nutraceuticals.

Whether you need a bottle labeling system for high-volume production or a flexible solution for cylindrical containers, the R322 ensures efficient, consistent, and cost-effective labeling at speeds up to 3,000 IPM.

Features and Benefits

- Heavy duty system framework – Built for durability and continuous production.

- 6” wide x 8’ long Delrin chain conveyor – Ensures smooth product handling.

- All AC drives – Reliable performance and reduced maintenance.

- Product metering wheel & photoelectric product sensor – Provides precise product control and label placement.

- High-speed SL2000 stepper driven label applicator – Digital control for accurate, repeatable labeling.

- Encoder with speed following from wrap station to SL2000 – Guarantees synchronized performance.

- 16” label roll capacity on 3” core – Maximizes uptime, reduces frequent roll changes.

- 6.25” wide web capacity – Handles a wide range of label sizes.

- 15” long high-speed wrapping station – Ideal for secure wrap-around labeling of bottles and cylindrical products.

- Job save menu & multi-level control system – Streamlines repeat jobs and operator efficiency.

- UL certified NEMA 12 control enclosure – Ensures compliance, safety, and reliability.

- Maximum Speed & Capacity – Dispense labels up to 3,000 inches per minute, meeting the fastest production demands.

- Large Roll Capacity – 16” OD roll capacity reduces downtime and improves workflow efficiency.

- Compact & Powerful Design – Dimensions: 59” W x 97” L x 64” H, with shipping weight approx. 1,160 lbs.

- Energy-Efficient Electric Drive – Operates at 120 VAC for optimal power usage.

- Flexible Integration – Designed to fit seamlessly into existing automatic production lines.

Applications

- Food & Beverage Packaging – bottles, cans, jars.

- Cosmetics & Personal Care – lotions, shampoos, creams.

- Pharmaceutical & Nutraceutical Products – vials, supplements, medicine bottles.

- Industrial Containers – lubricants, household goods, cleaning products.

Why Choose the Universal R322?

- High-Speed Bottle Labeling for beverage, cosmetic, and pharmaceutical industries.

- Accurate Label Placement reduces waste and ensures consistent branding.

- Durable & Industrial-Grade Build guarantees long service life in demanding environments.

- Scalable Options – Compatible with accessories like spin-in-place wrapping, clear label sensors, and extended conveyors.

- Cost-Effective Labeling System – Minimize downtime, maximize throughput.

The Universal R322 High-Speed Round Product Labeling System is the ultimate solution for manufacturers who demand speed, precision, and reliability in high-volume production. Engineered with a heavy-duty framework, premium industrial components, and a high-speed SL2000 stepper-driven applicator, the R322 delivers accurate, repeatable labeling at speeds up to 3,000 IPM for bottles, jars, vials, and other cylindrical products. Its 8’ Delrin chain conveyor, 16” roll capacity, and encoder-synchronized wrap station minimize downtime while ensuring flawless placement on every container. Compact yet powerful, energy-efficient, and designed for seamless integration into existing lines, the R322 provides durable, cost-effective labeling across food and beverage, pharmaceutical, cosmetic, nutraceutical, and industrial applications, making it the ideal choice for maximizing throughput without sacrificing quality.

Contact Us Today for Pricing